Copyright Notice and Disclaimer:

All technical analyses and functional descriptions in this article belong to the author of this article, and the ultimate right of interpretation belongs to the product manufacturer. The product parameters and performance data quoted in this article are for reference only. The actual product performance may vary due to specific parameters, use of the environment, individual differences and other factors.

ODM/OEM Contact Information:

Ricardo

sales28@seemax.com.cn

WeChat: seemaxfan999

Table of Contents

1. Key Motor Torque Requirements in OEM Pedestal Fan Design

2. Motor Power Rating and Efficiency Parameters for Pedestal Fan OEM Projects

3. Rotor–Stator Geometry and Magnetic Circuit Design in Pedestal Fan Motors

4. Motor Winding Configuration and Copper Fill Factor in OEM Pedestal Fans

5. Bearing System Selection and Its Impact on Motor Noise in Pedestal Fan Design

6. Thermal Management and Overheat Protection Parameters in Pedestal Fan Motors

7. Motor Start-Up Characteristics and Soft-Start Algorithms for OEM Pedestal Fans

8. Vibration Control and Dynamic Balancing Specifications in Pedestal Fan Motor Design

9. Compliance, Safety Standards, and Reliability Criteria for OEM Pedestal Fan Motors

1. Key Motor Torque Requirements in OEM Pedestal Fan Design

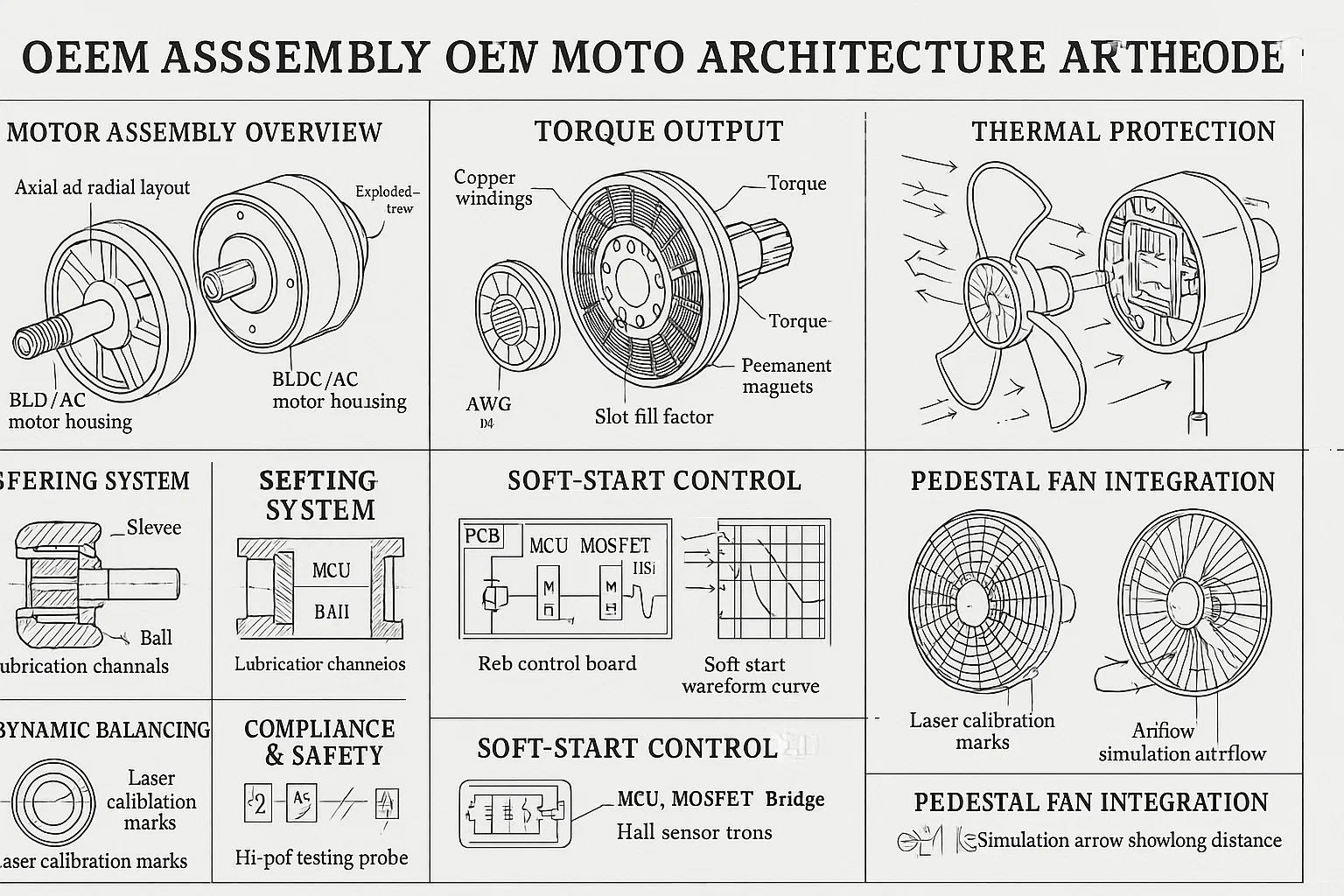

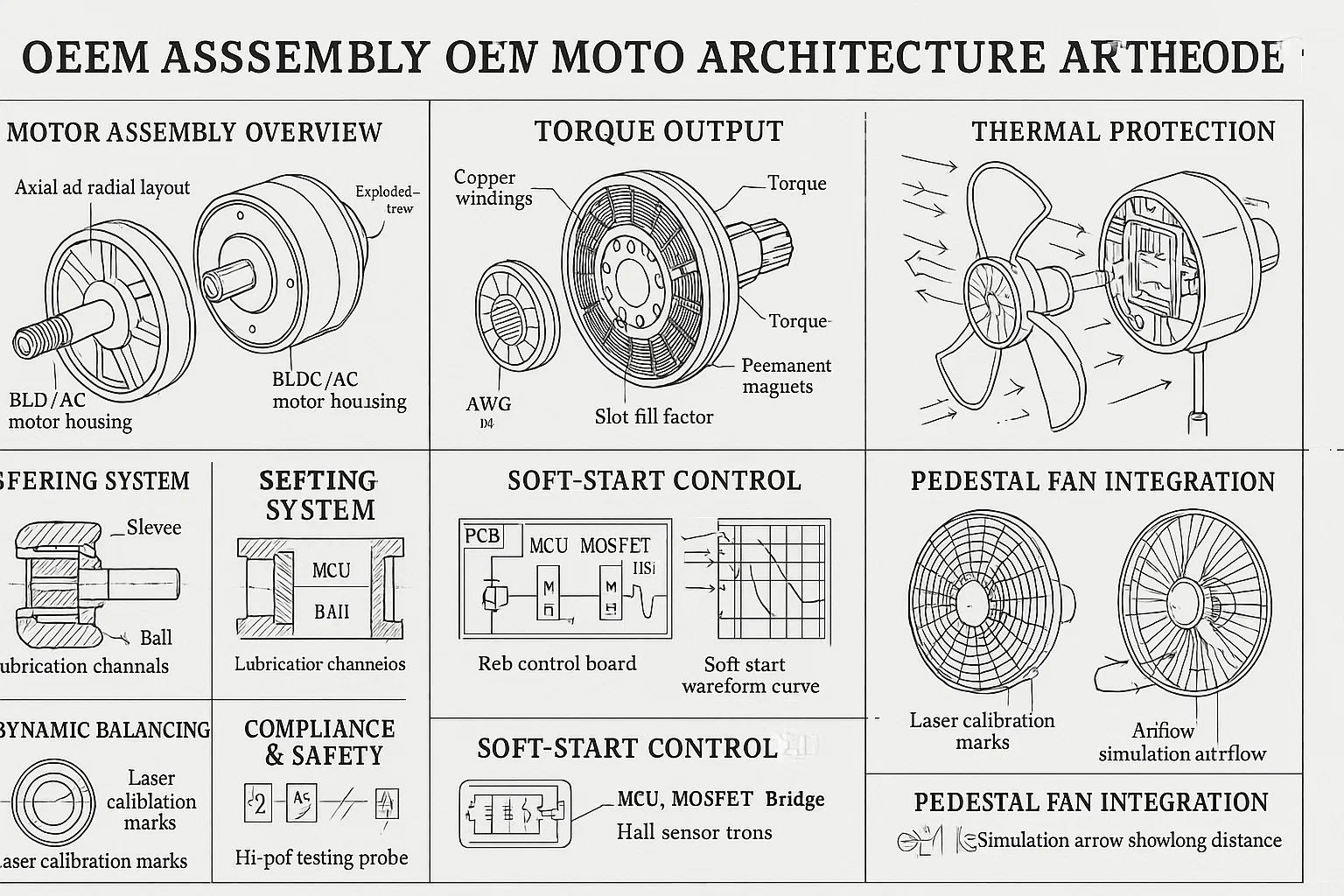

Motor torque is one of the most decisive performance indicators when developing an OEM pedestal fan. Torque determines whether the fan can initiate rotation smoothly, maintain stable airflow across different speed modes, and sustain long-distance air delivery—one of the unique selling points of high-performance pedestal fans. For OEM projects, torque must be engineered not just to meet basic operation, but to align with brand-specific airflow performance specifications. In pedestal fan applications, torque requirements often involve three core considerations: starting torque, running torque, and load-bearing torque. Starting torque ensures the motor can overcome static friction and aerodynamic resistance when the blades first begin rotating. Fans with large-diameter blades or aerodynamic high-pitch blade designs require higher starting torque, especially in BLDC motor systems that use soft-start algorithms. Running torque determines whether the motor can maintain stable RPM under continuous airflow load without speed fluctuation, noise surges, or thermal drift. Load-bearing torque refers to the motor’s capacity to maintain rotation while delivering long-distance airflow, often requiring a torque profile optimized for mid-to-high RPM performance. Torque requirements influence rotor magnet strength, stator slot design, winding configuration, and even the fan blade geometry. In an OEM development environment, torque calibration is frequently adjusted across multiple prototype iterations to match brand airflow expectations—especially for premium models targeting 6–9 meter air throw distance. Therefore, defining torque requirements early in the project is essential for avoiding costly downstream redesigns.

2. Motor Power Rating and Efficiency Parameters for Pedestal Fan OEM Projects

Motor power rating directly determines energy consumption, mechanical output capability, and thermal performance. In pedestal fan OEM development, motor power typically ranges from 18W for compact models to 45W or higher for long-distance airflow units. The power specification must strike a balance between performance, noise, energy efficiency, and safety compliance. Efficiency is an equally critical parameter. High-efficiency motors not only reduce energy consumption but also minimize heat generation, which directly improves the fan’s noise and durability. OEM pedestal fans increasingly adopt BLDC motors because their efficiency can reach 80–90%, compared to 40–60% in traditional AC shaded-pole motors. Higher efficiency also supports more advanced airflow modes, such as stepless speed control, ECO mode, and precise airflow curve shaping. The power rating must also align with regional energy standards. For example, fans exported to Europe must comply with ERP directives, while fans in the U.S. may need to meet DOE or ENERGY STAR requirements. These regulations impose strict limits on input wattage per airflow output (CFM/W), making motor efficiency a central focus of OEM engineering. A well-optimized motor will maintain stable performance across multiple load conditions while avoiding excessive thermal buildup. Because pedestal fans often operate for extended periods—8 to 12 hours per day in some households—motor efficiency is not just a technical metric but a real-world user experience factor. Energy-efficient motors run cooler, last longer, and produce more consistent airflow without noise spikes.

3. Rotor–Stator Geometry and Magnetic Circuit Design in Pedestal Fan Motors

The geometry of the rotor and stator, along with the layout of the magnetic circuit, forms the structural foundation of a pedestal fan motor’s performance. These components determine how efficiently electromagnetic force is converted into rotational motion, how much torque is available across the speed range, and how smoothly the motor operates. In BLDC motors—now widely integrated in premium OEM pedestal fan designs—the rotor typically uses high-grade NdFeB permanent magnets. The number of poles, magnet thickness, and arc coverage directly influence torque ripple, cogging torque, and acoustic characteristics. A carefully engineered rotor geometry can drastically reduce vibration and improve airflow uniformity. The stator design involves considerations such as slot number, lamination thickness, and iron-core material. Thinner laminations reduce eddy current losses, increasing motor efficiency and reducing heat. Slot shape affects magnetic flux density and the overall cogging profile, which influences noise levels during low-speed operation. For OEM pedestal fans emphasizing quiet performance—often under 30 dB—the stator geometry must be optimized for minimal electromagnetic noise. The magnetic circuit is another area where engineering decisions have major impact. Air-gap length, magnetic flux balance, and rotor-stator alignment must be controlled to ensure smooth rotation with minimal torque ripple. Premium motors may adopt concentrated windings or distributed windings depending on the desired torque-speed curve. OEM clients often differentiate product tiers based on motor smoothness and airflow stability, and these characteristics are directly influenced by rotor-stator engineering. As a result, advanced OEM suppliers frequently utilize simulation tools—such as finite element analysis (FEA)—to model magnetic flux paths and optimize geometry before tooling begins.

4. Motor Winding Configuration and Copper Fill Factor in OEM Pedestal Fans

Winding configuration plays a central role in determining a motor's torque characteristics, efficiency, temperature rise, and acoustic behavior. Manufacturers can choose between multiple winding topologies—distributed winding, concentrated winding, delta winding, or star (Y) winding—each with distinct performance profiles. The copper fill factor—the percentage of coil area occupied by copper wire—is one of the most important variables in winding design. Higher copper fill factor typically results in: Lower resistive losses Higher motor efficiency Increased torque capability Lower heat generation during operation However, achieving high fill factor requires precision in coil winding and slot geometry, posing challenges for mass-production consistency. Wire gauge selection determines the motor’s current-carrying capability. Thinner wire allows more turns but increases resistance, while thicker wire increases torque but makes winding more difficult. The optimal balance must be determined based on the target airflow output, noise limit, and expected duty cycle. Winding pattern also affects acoustic characteristics. Irregular winding distribution can cause imbalance in magnetic flux density, leading to tonal noise or harmonic vibration—unacceptable for premium pedestal fans that aim for 20–28 dB noise levels. Therefore, winding configurations must be tightly controlled to ensure uniformity across production batches. OEM projects often require custom winding profiles to achieve brand-specific airflow curves. By refining winding turns, phase resistance, and coil layout, engineers can fine-tune the motor’s torque-speed characteristics to deliver stronger long-distance airflow or quieter low-speed operation depending on client priorities.

5. Bearing System Selection and Its Impact on Motor Noise in Pedestal Fan Design

The bearing system is one of the most influential components affecting a pedestal fan motor’s noise performance, lifespan, and rotational stability. OEM developers must choose between different bearing types—primarily sleeve bearings and ball bearings—depending on product positioning, expected airflow performance, and brand requirements. Sleeve bearings are commonly used in cost-efficient pedestal fans. Their operation relies on an oil-lubricated metal sleeve that provides smooth rotational motion. Sleeve-bearing motors can operate quietly at lower RPM, making them suitable for fans intended for bedrooms or low-noise environments. However, sleeve bearings have a shorter lifespan, are more sensitive to temperature changes, and may produce noise as lubrication evaporates over time. Ball bearings offer improved durability, higher load tolerance, and better performance at elevated RPMs. They are preferred for pedestal fans designed for long-distance air throw, where motors must operate at higher torque and speed. Ball bearings are also more resistant to heat, making them ideal for fans expected to operate in warm climates or run continuously for long hours. Bearing alignment, lubrication type, and sealing also influence overall noise. Even small deviations in bearing concentricity can produce harmonic vibrations amplified by the fan housing. Therefore, premium OEM pedestal fans typically undergo multiple rounds of dynamic noise testing to ensure consistent performance. Fans targeting ultra-quiet performance—below 30 dB—require highly engineered bearings with precise tolerances, stable lubrication, and minimal friction. Additionally, OEM projects must consider cost-performance trade-offs: a ball-bearing motor may increase cost by 20–40%, but significantly extend lifespan and enhance acoustic stability.

6. Thermal Management and Overheat Protection Parameters in Pedestal Fan Motors

Thermal management is essential to ensure safety, durability, and stable performance in OEM pedestal fan motors. Excessive heat can cause insulation breakdown, winding degradation, accelerated bearing wear, and even motor failure. Therefore, thermal design must include both passive cooling structures and active protection mechanisms. Temperature rise must be controlled to meet regulatory standards, usually under 70–80°C for Class B insulation systems. Motors designed for long-distance airflow typically operate at higher loads, making thermal efficiency a critical parameter. Core thermal management methods include: High-efficiency lamination materials to reduce iron loss Optimal slot-filling to minimize resistive losses Airflow-guided motor housings to enhance heat dissipation Use of thermally conductive but electrically insulating varnish Integration of heat sinks in BLDC motor housings Another key parameter is overheat protection. Most motors integrate thermal fuses or PTC thermistors that cut off power when temperature exceeds safe limits. In BLDC motors, firmware-based thermal throttling dynamically reduces RPM when overheating risk is detected. For OEM projects exporting to multiple markets, thermal management must also comply with varying environmental conditions. Motors sold to Middle Eastern markets require higher thermal tolerance compared to those used in Europe or Japan. Therefore, OEM developers often create multiple thermal profiles for different versions of the same fan model. Advanced pedestal fans combine motor cooling strategies with airflow path optimization, ensuring the motor receives continuous ventilation from the blades—an elegant integration of aerodynamics and electrical engineering.

7. Motor Start-Up Characteristics and Soft-Start Algorithms for OEM Pedestal Fans

The start-up characteristics of a pedestal fan motor greatly influence user experience, motor safety, and long-term reliability. OEM designs must ensure smooth, vibration-free, and noise-free start-up under varying load conditions, especially when using large-diameter blades or high-pitch blade angles. Traditional AC motors rely on capacitor-start mechanisms. The capacitor creates a phase shift to generate the initial torque needed to begin rotation. Capacitor characteristics—capacitance value, tolerance, temperature rating—directly affect start-up smoothness. In modern BLDC motors, soft-start algorithms have become a key differentiator for premium pedestal fans. Instead of instant acceleration, the motor ramps up RPM gradually over several hundred milliseconds. This provides multiple advantages: Reduces mechanical stress on the motor Minimizes inrush current Prevents sudden noise bursts Enhances perceived product quality Extends bearing and blade life Start-up torque profiles also require careful tuning. If torque is too low, the fan may stall; if too high, it may cause vibration or unwanted noise. BLDC firmware allows engineering teams to fine-tune these curves precisely. Fans designed for smart-home ecosystems—WiFi fans, app-controlled fans—often integrate additional start-up control modes, such as anti-stall protection, auto-recovery mechanisms, and torque compensation algorithms based on ambient temperature or blade resistance. In OEM development, start-up behavior is repeatedly tested across different voltage conditions (e.g., 100–120V, 220–240V), humidity ranges, and temperature fluctuations to ensure global stability.

8. Vibration Control and Dynamic Balancing Specifications in Pedestal Fan Motor Design

Vibration control is one of the most crucial engineering aspects in pedestal fan design, as excessive vibration not only produces noise but also shortens motor lifespan, causes oscillation instability, and reduces airflow efficiency. OEMs must engineer both the motor and the fan blade to achieve optimal dynamic balancing. Dynamic balancing involves distributing mass around the rotor and blade assembly so that rotational forces remain symmetrical. Even small imbalances—such as 0.05–0.1 grams—can create noticeable vibration at high RPM. To reduce this, OEM developers use: Precision rotor balancing machines Laser measurement systems Automated balancing with resin or weight inserts Multi-point blade mass calibration In BLDC fans, torque ripple from the motor’s electromagnetic cycle may also introduce micro-vibrations. Engineers address this by optimizing slot-pole combinations and using skewed stator designs. Motor housing construction influences vibration levels as well. Materials such as reinforced ABS, aluminum alloy housings, or composite frames help dampen vibration energy. Proper isolation between the motor and pedestal pole prevents vibration from transferring into the structure. The overall vibration performance is often measured using RMS displacement, acceleration coefficients, and harmonic noise analysis. Fans designed for ultra-quiet operation—often below 30 dB—require multi-stage balancing and precise engineering from both electrical and mechanical teams. OEM projects increasingly include vibration testing as part of automated end-of-line (EOL) inspection, ensuring consistent performance across mass production.

9. Compliance, Safety Standards, and Reliability Criteria for OEM Pedestal Fan Motors

OEM pedestal fan motors must meet strict international compliance, safety, and reliability standards to ensure safe operation, durability, and consumer trust. These standards influence nearly every design decision, from insulation class to wiring layout, motor materials, and thermal protection. Common global certifications include: CE (Europe) GS (Germany) UL/FCC (United States) ETL (North America) CCC (China) PSE (Japan) SAA (Australia) Each certification covers aspects such as electrical safety, electromagnetic compatibility (EMC), chemical material restrictions (RoHS), and structural durability. Motors must also comply with insulation standards such as Class A, B, or F, depending on temperature rise requirements. Reliability testing is equally essential, typically covering: Hi-pot testing Insulation resistance testing Leakage current testing Vibration endurance Thermal cycling 3000–5000-hour continuous operation tests Overload and locked-rotor tests OEM clients often request custom reliability validation based on target markets. For example, Southeast Asian regions may require high humidity resistance, while Middle Eastern markets require higher thermal tolerance. By meeting these standards, OEM pedestal fan motors achieve not only regulatory compliance but also build trust with consumers who expect consistent performance and long-term durability.

Conclusion

Developing an OEM pedestal fan motor involves a complex integration of mechanical engineering, electrical design, thermal management, acoustic optimization, and compliance verification. Key parameters such as torque, efficiency, winding configuration, bearing type, thermal protection, and vibration control determine the final product’s airflow performance, sound levels, energy consumption, and overall reliability. A well-engineered motor can differentiate an ordinary pedestal fan from a premium one—delivering stronger airflow, quieter operation, longer lifespan, and smarter control. By understanding and optimizing these critical motor design parameters, OEM brands can create pedestal fans that meet global standards while exceeding customer expectations. Ultimately, successful OEM development is about synergy—aligning engineering capabilities, production standards, and brand goals to design a fan motor that performs flawlessly in real-world conditions.

FAQ — Common Questions About OEM Pedestal Fan Motor Design

1. Why do premium pedestal fans prefer BLDC motors over AC motors?

BLDC motors offer higher efficiency, lower noise, more stable RPM control, and longer lifespan. They support stepless speed control and advanced airflow modes, ideal for high-end fan designs. 2. What causes pedestal fan motors to heat up during long operation?

Heat is typically caused by electrical losses in windings, magnetic losses in the core, insufficient airflow around the motor, or low-efficiency designs. Proper thermal management and high-quality copper windings reduce heat significantly. 3. Are ball bearings worth the higher cost in pedestal fan motors?

Yes. Ball bearings last longer, tolerate higher temperatures, reduce vibration, and maintain stable RPM at high speeds—making them ideal for long-distance airflow fans. 4. Why do some pedestal fans vibrate more than others?

Vibration often results from poor dynamic balancing, uneven blade mass, rotor misalignment, or low-quality bearings. OEM fans with precise balancing maintain much smoother operation. 5. Can OEM clients request customized airflow or motor performance?

Absolutely. OEM developers frequently customize torque curves, winding configurations, firmware algorithms, noise profiles, and airflow patterns to match brand specifications.