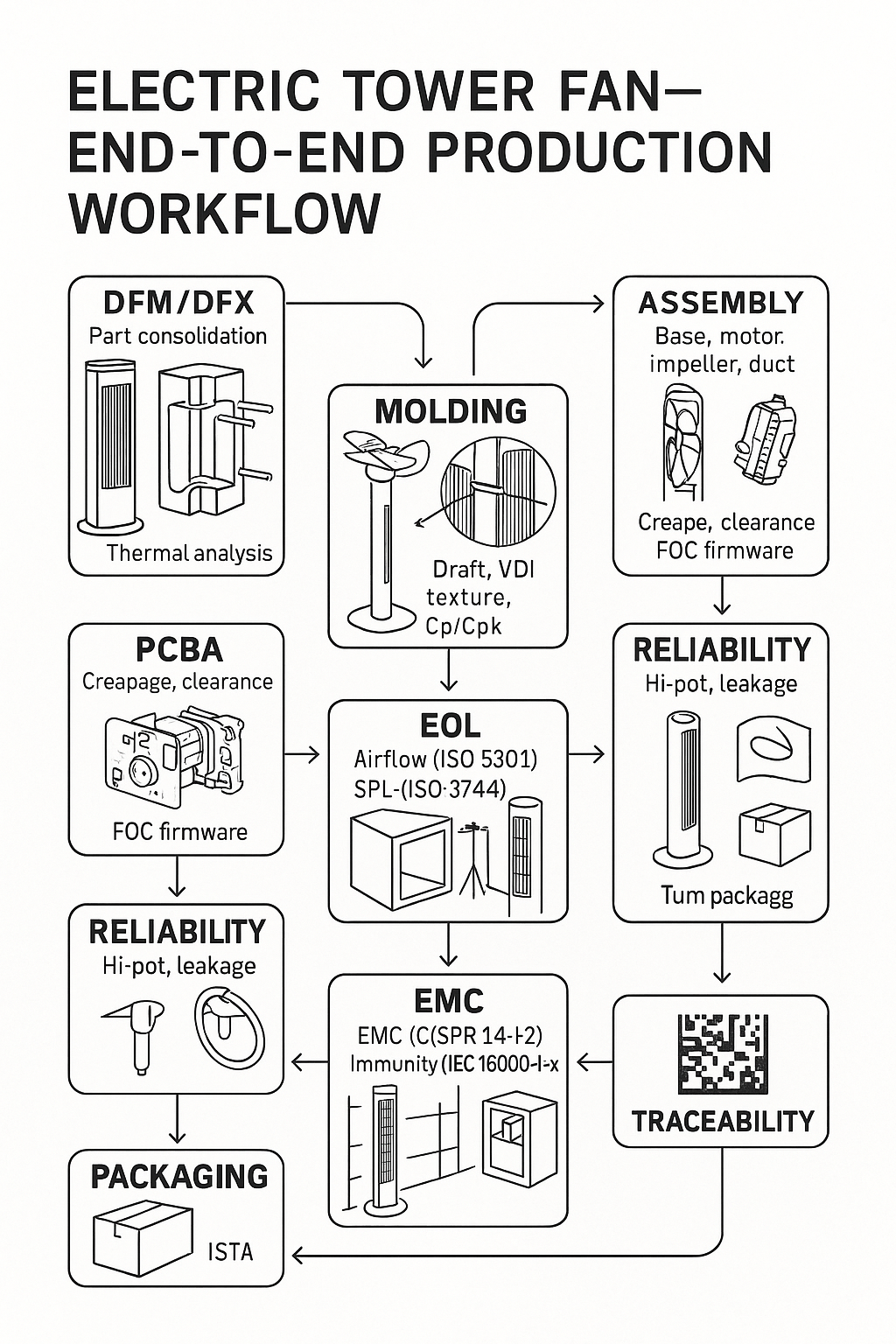

Electric Tower Fan DFM baseline: part consolidation, datum strategy, and draft angles

Design-for-Manufacture (DFM) is the first lever in an end-to-end electric tower fan production process because tooling quality is a one-way door. Start by consolidating cosmetic bezels, duct ribs, and latch tabs so each molded part serves multiple functions—structure, acoustic damping, and assembly location. Establish a clear datum scheme (primary plane on the base, secondary on the duct spine, tertiary on the outlet bezel) so the tolerance stack-up closes with simple fixturing. Maintain 1.0–1.5° draft on textured surfaces (VDI 12–18) and ≥0.5° on hidden faces to ensure robust de-molding without scuffing that later reads as cosmetic defects. Add 0.5–0.8% uniform shrink for ABS/PC in the CAD model; call out ribs ≤ 60% wall thickness to prevent sink.

DFX beyond DFM: Design-for-Assembly, Service, and Test for the Electric Tower Fan

Design-for-Assembly (DFA) reduces assembly cycle time. Use symmetric snap-fits that don’t require orientation decisions, poka-yoke tabs keyed to prevent upside-down installation of the crossflow impeller, and captive screws where torque control matters (motor cradle). Design-for-Service (DFS) exposes the power PCB with four fasteners and a single harness so after-sales repair stays under five minutes. Design-for-Test (DFT) reserves a 4-pin header (TX/RX/GND/VBUS) for firmware flashing and end-of-line (EOL) telemetry; route motor currents to a low-ohmic shunt for closed-loop airflow calibration in production.

Cost-down with engineering controls: should-cost, value analysis, and ramp readiness

A should-cost model for an electric tower fan breaks the BOM into molded plastics (45–55%), motor/PCBA (25–35%), hardware/rubber (5–10%), and packaging/logistics (10–15%). Value Analysis/Value Engineering (VA/VE) swaps painted surfaces for in-mold textures where feasible, converts threaded inserts to heat-set brass only where pull-out > 400 N is required, and transitions from 2-shot light pipes to single-shot PC with post-laser etch. Build ramp readiness into the plan: dual-source the motor magnets and ABS/PC resin early to prevent capacity shocks; require tooling with interchangeable gate inserts so flow balance can be tuned after first article inspection (FAI).

Which Polymers and Flame Ratings Enable a Durable Electric Tower Fan (ABS/PC, PBT-GF) While Meeting UL94, RoHS, and REACH?

Housing and vertical duct materials for the Electric Tower Fan: ABS/PC vs. HIPS vs. PP-T

The outer housing and tall vertical duct live at 45–65 °C bulk plastic temperature during long-term operation. ABS/PC (Tg ≈ 110–125 °C, Izod 200–400 J/m) keeps stiffness under heat and resists environmental stress cracking from household cleaners. HIPS is cheaper but softens earlier (HDT around 70–85 °C) and shows creep on the outlet frame; use only on non-load panels. PP-T (talc-filled polypropylene) offers good cost and density benefits but requires thicker ribs to hit the same stiffness as ABS/PC, which increases cooling time and tooling cost. For a long-life electric tower fan, ABS/PC is the typical primary resin for the duct and front bezel.

Impeller and motor cradle selections: PBT-GF and PA-GF in the Electric Tower Fan

The crossflow impeller benefits from PBT-GF15–30: low moisture uptake, excellent dimensional stability, and higher heat deflection around 150–170 °C. Glass fiber keeps chord twist under load to maintain a flat velocity profile; aim for radial run-out < 0.2 mm. The motor cradle can be PA6-GF30 or PBT-GF30 depending on vibration and temperature goals; both handle sleeve or ball-bearing preload while limiting structural resonance near the blade-pass frequency.

Regulatory compliance: UL94, RoHS, REACH, and documentation for the Electric Tower Fan

Choose flame ratings per proximity to mains. For PCBA carriers and the inlet filter frame near the power supply, select UL94 V-0 materials; for cosmetic housings on double-insulated designs, UL94 HB or V-2 is usually acceptable (verify with your NRTL). Document RoHS (10 restricted substances at <0.1% w/w, Cd <0.01%) and REACH SVHC screening with resin supplier certificates of analysis (CoA). Keep a materials declaration and IMDS entry for OEM customers; it lowers friction during audits and speeds market access for the electric tower fan.

How Are Injection Molding Gates, Runners, and Texture Specs Qualified for Electric Tower Fan Housings and Ducts (Moldflow, Cp/Cpk ≥ 1.33)?

Moldflow simulation for the Electric Tower Fan: weld lines, air traps, and cooling balance

Run Moldflow with resin-specific viscosity curves to predict fill time, weld-line locations, and air traps. For the tall duct, position a fan gate or edge gate near the neutral bending axis so knit lines hide under the internal honeycomb frame. Add vacuum vents at the top third where air traps are predicted; vent depth ≈ 0.02–0.04 mm for ABS/PC. Simulate cooling to ensure <2 s temperature delta across the outlet frame; asymmetric cooling telegraphs as twist that later requires costly post-machining.

Gate/runner hardware and tool steel choices for the Electric Tower Fan

Hot runners reduce runner waste and improve flow balance on large bezels; cold runners can be fine for small internal brackets. Use H13 or 1.2344 for cores with thin ribs; polish to Ra ≤ 0.4 µm where airflow touches to minimize boundary layer growth in the diffuser. Define texture with VDI numbers on the drawing; pair them with a 1.0–1.5° draft requirement and note “no texture in critical airflow path” to avoid surface-induced turbulence.

Dimensional qualification and capability for the Electric Tower Fan: Cp/Cpk goals

Critical-to-function (CTF) dimensions—duct width/straightness, impeller bore, motor cradle height—require Cpk ≥ 1.33 at pilot and ≥ 1.67 at mass production. Sample n=30 parts per cavity for each CTF at T1 and T2. Establish golden samples locked in a metrology cabinet and re-verify every 10k pieces or any time the tool is serviced. Capability drift on the duct flange flatness is the #1 root cause of non-uniform airflow complaints; guard it with SPC and tool maintenance intervals.

What Industrialization Path Brings the BLDC Motor and Power PCB of an Electric Tower Fan to Mass Production (FOC Control, Creepage/Clearance, PCB DFM)?

Motor industrialization for the Electric Tower Fan: winding, balancing, and torque curves

Freeze the stator slot/pole combination (e.g., 12N14P), wire gauge, and winding pattern; require 100% resistance and inductance measurement at the motor vendor. Specify rotor dynamic balance to ISO 21940 G2.5 with residual vibration <2.8 mm/s RMS at the rated rpm. Capture motor torque–speed curves at 12–15 operating points to populate firmware lookup tables; this reduces startup overcurrent and stabilizes airflow at low speed.

PCB DFM and safety: creepage/clearance and reinforced isolation for the Electric Tower Fan

A global electric tower fan usually runs on 100–240 Vac. Maintain clearance ≥ 3.0 mm and creepage ≥ 5.0–6.4 mm between primary and SELV circuits (pollution degree 2, basic vs. reinforced per IEC 62368-1/60335). Use slots under optocouplers and transformers to stretch creepage on compact boards. Keep Y-capacitors (line/earth) rated appropriately (e.g., CY2, 2.2 nF, 250 Vac) and X-capacitor (line/neutral) with bleeder resistor to meet surge and discharge requirements. Place a fusible resistor or T-fuse at the inlet to meet abnormal operation tests. Design test points for ICT and a small bed-of-nails to cover power rails, Hall sensors, and gate drivers.

FOC firmware, protection, and production programming for the Electric Tower Fan

Implement sinusoidal FOC (Field-Oriented Control) with a 20–25 kHz PWM to push switching noise above hearing. Add stall detection, locked-rotor current limit, thermal derating from an NTC near the MOSFETs, and brown-out recovery. Calibrate a current-to-CFM (or m³/h) curve per speed step on a small orifice rig; store coefficients in cal-EEPROM so airflow is consistent despite motor tolerances. Use a serial bootloader so firmware release candidates can be loaded at EOL with version lock; log the firmware hash to the unit’s 2D barcode.

How Do APQP/PPAP, PFMEA, and Control Plans Ensure Electric Tower Fan Quality from IQC → IPQC → OQC (SPC, MSA/Gage R&R)?

APQP phases and PPAP deliverables for the Electric Tower Fan

Follow APQP through concept, design & development, process development, product & process validation, and feedback/continuous improvement. For PPAP, assemble the DFMEA, PFMEA, Control Plan, balloon drawings, material certs, MSA studies, PSW (Part Submission Warrant), and capability studies. For a multi-cavity duct tool, PPAP at Level 3 is typical; shipments only start after PSW is signed.

IQC → IPQC → OQC: gatekeeping quality for the Electric Tower Fan

Incoming Quality Control (IQC) validates resin lots (MFR, color Lab*), motor sub-assemblies (resistance/inductance), and PCBs (X-ray for voids on power devices). Use AQL 0.65/1.0/2.5 for critical/major/minor. In-Process QC (IPQC) checks torque on motor screws, adhesive bead width on felt seals, and airflow uniformity on a sampling basis after the outlet module is joined. Outgoing QC (OQC) performs 100% Hi-Pot, ground bond (if Class I), and cosmetic inspection under 1000–1500 lux lighting with a 30 cm viewing distance per your cosmetic standard.

SPC and MSA: keeping measurement honest in the Electric Tower Fan factory

Choose X-bar/R or I-MR charts on duct flange flatness, impeller bore diameter, and EOL current draw. Investigate any Western Electric rules violations before they cascade into non-uniform airflow complaints. Run Gage R&R on airflow fixtures and sound chambers; aim for %GRR < 10% of tolerance to ensure your pass/fail is trustworthy. Re-calibrate microphones and anemometers on a 6-month cycle; log certificates in the device history record (DHR).

What Assembly Line Sequencing and End-of-Line Tests Validate Electric Tower Fan Airflow, Noise, and Balance (ISO 5801, ISO 3744, G2.5)?

Electric Tower Fan assembly sequence: takt-time, fixtures, and mistake-proofing

A reliable assembly line starts with the oscillation base and rises upward to the outlet grille. Typical sequence: base + spindle → motor cradle + PCB + harness → impeller + scroll → vertical duct + diffuser → honeycomb straightener → outlet grille → safety screens → base cover. Set takt time at 20–30 s/station for a 1k-units/day line. Use torque drivers (±10%) with traceability, and poka-yoke pins that physically block the wrong duct half from entering the ultrasonic welder.

EOL functional tests for the Electric Tower Fan: airflow, current, and acoustics

At the End-of-Line, measure: (1) air volume flow via a calibrated outlet grid or compact orifice box; typical medium-speed targets are 300–450 m³/h; (2) motor current and power factor at each speed; (3) SPL in a semi-anechoic booth aligned to ISO 3744; and (4) temperature rise on a 2-min step test to catch friction or mis-alignment. Compare to a golden unit; any deviation > ±10% airflow or +3 dB(A) triggers re-work.

Balance and vibration control to G2.5 for the Electric Tower Fan

Even with a balanced rotor from the motor vendor, final assembly can stack tolerances. Spin-test the installed impeller/rotor and apply trim weights or adhesive dots opposite the heavy spot. The pass criterion is vibration velocity < 2.8 mm/s RMS at rated speed measured at the duct midpoint. Low vibration doesn’t just reduce noise; it keeps the exit velocity profile uniform through the product’s life.

Which Reliability & Safety Protocols Must an Electric Tower Fan Pass Before SOP (IEC 60335-2-80, HALT/HASS, ISTA Drop/Vibration)?

Safety for the Electric Tower Fan: hi-pot, leakage, ball pressure, and glow-wire

For Class II designs (no earth), perform Hi-Pot at 1.5–2.0 kVac for 1 min between mains and SELV; keep leakage current below the NRTL’s limit (often <0.75 mA for appliances). Plastic near live parts must pass ball pressure at 125 °C (or higher for V-0 parts). Conduct the glow-wire test (usually 550–750 °C as applicable) on plastic supports to confirm flame resistance, per IEC 60695 references within IEC 60335-2-80 (household fans).

Reliability plan: life tests, temperature-humidity, and abuse for the Electric Tower Fan

Run a 1,000–2,000 h accelerated life test at 35–45 °C ambient, cycling oscillation every 10 min to exercise gears. Add temperature-humidity (e.g., 40 °C/93% RH for 96 h) to probe corrosion on connectors and long-term creep on the duct joints. Abuse corner cases include finger-probe compliance, ingress (dust screens), and tip-over to verify the fan shuts down safely.

Packaging and transport: ISTA for the Electric Tower Fan

Package validation follows ISTA 1A/2A/3A depending on distribution risk. A common regime: 10 drops from 76 cm on all faces/edges/corners for the shipper carton; random vibration at 1.15 Grms for 60 min/axis; and stack compression equal to the worst-case pallet height. Use double-wall cartons, EPE end-caps ≥ 25 mm, and a clamshell bag to prevent scuffing of textured bezels. Print orientation arrows so the long duct isn’t crushed under mis-stacking.

How Are EMC/EMI Requirements for an Electric Tower Fan Planned and Closed (CISPR 14-1/14-2, IEC 61000-4-2/3/4/5/6 Conducted & Radiated)?

Emissions plan for the Electric Tower Fan: CISPR 14-1 limits and pre-scan strategy

For household appliances, CISPR 14-1 governs conducted emissions (150 kHz–30 MHz) and radiated emissions (30–1,000 MHz). A practical target is 6 dB of margin at worst points to account for lot and setup variation. Pre-scan early with a LisN and current probes; raise PWM from 18 kHz to 20–25 kHz so the dominant switching energy avoids the most restrictive bands. Use a shielded harness for the motor phases if radiated hot spots appear near 120–200 MHz.

Immunity plan for the Electric Tower Fan: IEC 61000-4-x levels

Follow CISPR 14-2 immunity with the associated IEC 61000-4 tests: -4-2 ESD at ±4 kV contact/±8 kV air (many teams harden to ±8/±15 kV for margin); -4-3 radiated RF at 3 V/m (often tested at 10 V/m for premium SKUs); -4-4 EFT at ±1 kV on AC lines; -4-5 surge at ±1–2 kV line-to-line (depending on market); -4-6 conducted RF at 3 V; and -4-11 voltage dips/interruptions (e.g., 0% for 10 ms, 70% for 25 cycles). Define performance criteria: the fan may momentarily reduce speed but must self-recover without user intervention.

Design countermeasures for the Electric Tower Fan: filters, layout, and grounding

On the inlet, place an X-cap + common-mode choke + differential LC filter with damped snubbers across the bridge rectifier. Keep loop areas small on the half-bridge and route sense returns separately to the controller AGND star point. Tie the motor frame and any internal metal shields to PE (for Class I) or to a Y-cap reference (for Class II) to bleed common-mode noise. Add ferrites on the motor phases (200–300 Ω @ 100 MHz) and use a tight twist to reduce magnetic loop radiation. If pre-scan shows narrow-band peaks, spread-spectrum PWM can shave 3–6 dB with minimal control-loop impact.

What Traceability, Firmware Release, and Packaging/Logistics Controls Sustain an Electric Tower Fan Through Mass Production and After-Sales?

Traceability for the Electric Tower Fan: 2D barcodes, genealogy, and process data

Assign a unique Unit Serial Number (USN) encoded as a DataMatrix on the rating label. The USN links to genealogy—motor lot, PCBA lot & firmware hash, tool cavity IDs, resin lot, and EOL measurements (airflow, current, SPL). Keep these in a MES so field returns can be traced back to suppliers within minutes. For high-runner SKUs, include on-board non-volatile memory that stores cumulative hours and fault codes to accelerate root-cause analysis.

Firmware release and change control for the Electric Tower Fan

Treat firmware like hardware: maintain a version tree, change notes, and release candidate gates (bench, EMC pre-scan, 50-unit pilot). Sign binaries if the MCU supports it; lock the bootloader to production keys. At EOL, stamp the firmware checksum into the barcode and into the cloud MES record. When cost-down components change (e.g., MOSFET brand), rerun a limited regression focused on EMC, thermals, and acoustic noise.

Packaging & logistics: palletization, climate, and sustainability for the Electric Tower Fan

Standardize carton footprints to optimize container cube (e.g., 5-layer pallets × 12 cartons). For humid routes, include desiccant and humidity indicator cards. Print a quick-start guide on the inner flap to reduce paper inserts. Track carbon-equivalent emissions per unit shipped to support sustainability claims—lighter EPE and right-sized cartons typically cut logistics CO₂ by 5–10% for an electric tower fan program.

Conclusion: Building a Production-Ready Electric Tower Fan From Tooling to EMC Compliance

A successful electric tower fan production process is a tightly coupled system—DFM sets the stage for robust tooling, material choices hold shape under heat and time, and Moldflow-backed gating delivers predictable parts at Cpk ≥ 1.33. Industrializing the BLDC motor and PCB with correct creepage/clearance and FOC firmware ensures smooth, efficient airflow with low acoustic signatures. APQP/PPAP turns tribal knowledge into controlled processes; SPC and MSA keep measurement honest; and an EOL that measures airflow, current, vibration, and SPL provides statistical proof that each unit will perform in the field. Reliability and safety testing to IEC 60335-2-80 and transport validation to ISTA filter out early-life and logistics failures. Finally, CISPR 14-1/14-2 emissions and immunity sign-off close the loop, while traceability and disciplined firmware release management sustain quality at scale.

When these disciplines are executed together, the end product is not just compliant—it’s consistent. Your customer feels a uniform vertical sheet of air, hears a quiet hum instead of tones, and experiences long service life. Your factory sees fewer line stops, fewer re-works, and a cleaner yield ramp. That’s what “end-to-end” really means.

Frequently Asked Questions: Electric Tower Fan Production, Testing, and Compliance

Q1: What airflow and noise numbers should I target for a premium electric tower fan?

For a 1-meter-tall model, a solid mid-speed target is 350–450 m³/h at ≤ 50 dB(A) @ 1 m in a semi-anechoic environment. At low speed, keep ≤ 38 dB(A) so sleep mode is genuinely quiet.

Q2: Is UL94 V-0 mandatory for all plastic parts in an electric tower fan?

No. Use V-0 near the power supply and primary circuits; HB or V-2 suffices for purely cosmetic housings in Class II designs. Always confirm with your NRTL and local market requirements.

Q3: What are practical creepage/clearance rules for global mains on the fan’s power PCB?

For 100–240 Vac, design for ≥ 3.0 mm clearance and ≥ 5.0–6.4 mm creepage between primary and SELV, with reinforced isolation where required. Slots and wider creepage across the PCB surface help meet spacing without growing the board.

Q4: Which EMC test usually fails first on electric tower fan prototypes?

Conducted emissions around 150 kHz–1 MHz (bridge rectifier, switching supply, and PWM harmonics). Add common-mode chokes, improve input LC damping, and minimize hot-loop area near the MOSFETs.

Q5: How do I prove airflow uniformity on the factory floor without a full ISO chamber?

Use an orifice box for volume flow plus a 5×9 outlet grid with a calibrated anemometer. Track a uniformity index (stdev/mean) and set the limit at ≤ 10% at medium speed.

Q6: What capability metrics do buyers expect on the tall duct and impeller bore?

Most OEM buyers ask for Cpk ≥ 1.33 at pilot and ≥ 1.67 at mass production on duct flatness/straightness and impeller bore diameter. Share control charts in PPAP.

Q7: Do I need ball bearings to pass life testing on the electric tower fan?

Not necessarily. High-grade sleeve bearings can pass 1,000–2,000 h life tests if preload and lubrication are correct. If your design oscillates continuously or runs hot, ball bearings give more margin.

Q8: What’s the fastest way to de-risk EMC before formal testing?

Conduct a bench pre-scan: LisN for conducted emissions, near-field probes for radiated hot spots, ESD gun on plastics, and surge generator on AC input. Iterate filters and layout before booking the chamber.

Q9: How do we manage firmware versions across multiple factories?

Lock a signed release in your MES; EOL stations fetch the current version and write the hash to each unit’s barcode. Any unit with the wrong hash is blocked from pack-out.

Q10: What packaging spec prevents duct warpage during shipping?

Use EPE end-caps ≥ 25 mm, double-wall cartons, and a “no-stack higher than 5 layers” pallet rule. Validate with ISTA random vibration and compressive stacking to your region’s pallet height.

Q11: What are the must-keep documents for audits on an electric tower fan line?

Keep the DFMEA/PFMEA, Control Plan, calibration certificates, capability studies, COSHH/REACH/RoHS declarations, traceability map, EMC reports, and safety CB reports. Auditors ask for them first.

Q12: How do I tie returns data back to production lots?

Every unit’s USN links to genealogy in MES (motor/PCB lots, cavity IDs, EOL results). A quick Pareto on RMA codes usually points to a supplier lot or a specific cavity causing cosmetic or airflow issues.

Final Takeaway

If you embed DFM/DFX, validate polymers and tooling with data, industrialize the motor/PCB with safety spacing and FOC control, govern the factory with APQP/PPAP and SPC, and close EMC with design-in countermeasures, your electric tower fan won’t merely pass tests—it will scale cleanly, protect margin, and delight users with quiet, uniform airflow.