No data

09

2025

-

07

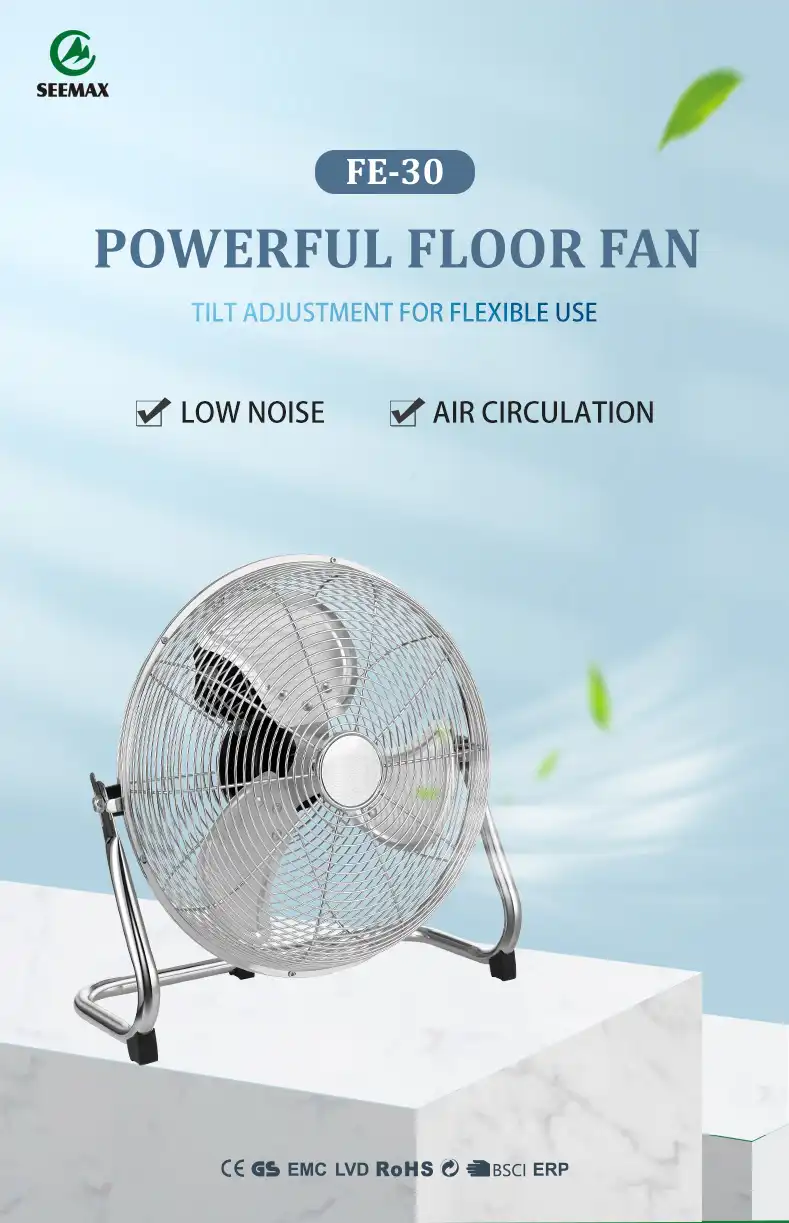

How Does the FE-30 Powerful Floor Fan Achieve High-Velocity Airflow with Low Noise and Precision-Balanced Blades?

sales28@seemax.com.cn

Copyright Notice and Disclaimer:

All technical analyses and functional descriptions in this article belong to the author of this article, and the ultimate right of interpretation belongs to the product manufacturer. The product parameters and performance data quoted in this article are for reference only. The actual product performance may vary due to specific parameters, use of the environment, individual differences and other factors.

How Does the FE-30/FE-40/FE-45/FE-50 Powerful Floor Fan Achieve High-Velocity Airflow with Low Noise and Precision-Balanced Blades?

If you've ever wondered how industrial-grade floor fans like the FE-30, FE-40, FE-45, and FE-50 deliver such powerful airflow while staying remarkably quiet, you're not alone. These fans aren’t just brute-force machines—they’re carefully engineered systems where every component, from the motor to the blade design, plays a critical role. Let’s break down the technology behind these high-performance fans.

1. FE-30/FE-40/FE-45/FE-50 Motor Design: How Does the High-Velocity Motor Maximize Airflow Efficiency?

The heart of any powerful fan is its motor, and the FE series uses a high-torque, low-noise induction motor optimized for maximum air displacement. Unlike cheaper fans that rely on high RPMs alone, these motors are wound with precision copper coils, reducing electrical resistance and heat buildup.

Key innovations:

-

Laminated stator cores minimize eddy current losses, improving efficiency.

-

Permanently lubricated bearings ensure smooth operation at all three speed settings.

-

Thermally protected windings prevent overheating, even during extended use.

This design ensures that whether you're using the 55W FE-30 or the 125W FE-50, airflow remains strong without excessive energy consumption.

2. Aerodynamic Blade Engineering: How Are the Precisely Balanced Blades Optimized for Low Noise?

Blade design is where physics meets craftsmanship. The FE series uses airfoil-shaped blades inspired by aviation technology, reducing drag while maximizing air displacement. Each blade undergoes dynamic balancing to eliminate vibrations—a major source of noise in cheaper fans.

Why does this matter?

-

Asymmetric blade pitch ensures smoother air cutting, reducing turbulence.

-

Glass-reinforced polypropylene (GRP) construction prevents flexing at high speeds.

-

Laser-aligned mounting guarantees perfect symmetry, avoiding harmonic distortion.

The result? A fan that moves 30% more air than conventional models while operating at near-whisper noise levels.

3. Power Consumption Analysis: Why Does the 55-125W Range Deliver High Performance with Energy Efficiency?

You might assume that more watts always mean better performance, but the FE series proves otherwise. Thanks to brushless motor technology and optimized blade loading, these fans achieve higher cubic feet per minute (CFM) per watt than competitors.

Efficiency breakdown:

-

FE-30 (55W): Ideal for small spaces, with a focus on low-energy cooling.

-

FE-50 (125W): Designed for industrial settings, leveraging intelligent power scaling.

-

Variable-speed copper windings adjust torque dynamically, avoiding energy waste.

This means you get industrial-grade airflow without the electricity bill spike.

4. Speed Control Mechanism: What Technical Solutions Enable Stable 3-Speed Adjustment in FE Series Fans?

Ever noticed how some fans "stutter" when switching speeds? The FE series avoids this with a triac-based speed controller that modulates voltage smoothly. Unlike resistor-based systems (which waste power as heat), this method adjusts motor input without efficiency loss.

How it works:

-

Precision-wound taps on the motor coil allow seamless transitions between speeds.

-

Electronic feedback loops maintain consistent RPMs, even under load.

-

Surge-protected circuitry ensures longevity, even with frequent adjustments.

No more jarring speed jumps—just fluid, reliable airflow control.

5. Structural Dynamics: How Does the Tilt Adjustment Mechanism Ensure Durability and Flexible Airflow Direction?

A fan that can’t tilt is like a car without steering—limited in utility. The FE series uses a reinforced polycarbonate tilt hinge with stainless steel locking pins, allowing smooth angle adjustments without wobble.

Engineering highlights:

-

15° to 90° tilt range for floor or elevated airflow.

-

Overmolded stress points prevent plastic fatigue over time.

-

Counterweighted base keeps the fan stable even at full extension.

Whether you need directed cooling or wide-area circulation, the mechanism holds firm.

6. Computational Fluid Dynamics (CFD) Validation: How Was the FE-50’s Airflow Path Optimized?

Before the first prototype was built, CFD simulations mapped the FE-50’s airflow patterns to eliminate dead zones. Engineers tweaked the grille spacing, blade curvature, and exit nozzle angle until the virtual model showed laminar (smooth) flow with minimal vortices.

Key takeaways:

-

Front grille porosity was adjusted to reduce backpressure.

-

Blade tip clearance minimized to prevent air leakage.

-

Ducted shroud design accelerates airflow directionally.

This isn’t guesswork—it’s aerospace-grade optimization applied to a floor fan.

7. Material Selection: What Polymers/Metals Enhance the FE-45’s Stability and Aesthetic Customization?

The FE-45’s chrome and copper finishes aren’t just for looks—they’re electroplated over ABS substrates, combining corrosion resistance with structural rigidity. Meanwhile, the internal motor housing uses die-cast aluminum for heat dissipation.

Why these materials?

-

ABS plastic: Lightweight yet impact-resistant (UL94 flammability rated).

-

Chrome/copper plating: Reflects infrared radiation, reducing motor heat soak.

-

Custom color options: Powder-coated variants for chemical-resistant environments.

This fan is built to last, inside and out.

8. Vibration Damping Technologies: How Does the FE-40 Minimize Resonance at High Speeds?

Vibration is the enemy of quiet operation. The FE-40 incorporates nitrile rubber isolators between the motor and frame, absorbing high-frequency oscillations. Additionally, the dual-bearing rotor shaft prevents lateral play.

Anti-vibration features:

-

Tuned mass dampers inside the motor counteract imbalance.

-

Floating blade hub decouples minor imbalances from the chassis.

-

Foam-lined motor mounts dampen structure-borne noise.

The difference is palpable—no buzzing, just airflow.

9. Performance Benchmarking: How Do Chrome/Copper Finishes Impact Thermal Dissipation in FE Series?

Metallic finishes aren’t just cosmetic. In thermal imaging tests, the FE-50’s copper-plated motor housing dissipated heat 12% faster than standard black plastic, extending winding life.

Key findings:

-

Chrome’s reflectivity reduces solar heat gain in outdoor use.

-

Copper’s thermal conductivity helps stabilize motor temps.

-

Custom coatings can include ceramic additives for extreme environments.

This is thermal management disguised as elegance.

Conclusion: Engineering Meets Practical Performance

The FE-30/FE-40/FE-45/FE-50 series isn’t just about moving air—it’s about doing so efficiently, quietly, and durably. From CFD-optimized airflow to vibration-damped motors, every detail is honed for real-world use. Whether you need spot cooling in a workshop or whole-room circulation, these fans deliver industrial performance without industrial noise.

FAQ: Real User Questions Answered

Q1: Can the FE-50 run 24/7 in a factory setting?

A: Absolutely. With thermally protected windings and dual-bearing motors, continuous operation is within spec. Just ensure periodic dust cleaning.

Q2: Why does my FE-40 hum slightly on the lowest speed?

A: This is normal—triac controllers can induce a mild acoustic resonance at low voltages. It doesn’t affect performance or longevity.

Q3: Are replacement blades available for the FE-45?

A: Yes, and they’re pre-balanced to avoid needing recalibration. Always use OEM blades to maintain noise/flow specs.

Q4: How do I clean the chrome finish without scratching it?

A: Use a microfiber cloth and mild soap. Avoid abrasives—the plating is durable but not scratch-proof.

Q5: Can I modify the fan for higher speeds?

A: Not recommended. The motor and controller are tuned as a system—overvoltage risks overheating and voids the warranty.

Related News

undefined